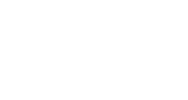

A weak phosphoric acid (40-55%) is produced from the reaction of PR with sulfuric acid, using a wet process. The obtained phosphoric acid is then used in the production of a series of liquid or solid fertilizers. The most important ones are single and triple superphosphates (SSP, TSP) and ammonium phosphates (MAP, DAP). Usually the plants are using flexible process technologies, allowing the manufacture of at least two products with interchangeable lines (e.g. TSP and DAP combination).

SSP is simple to produce but is nowadays less popular. TSP results from the reaction of PR with phosphoric acid, using the common Dorr-Oliver slurry granulation process. GTSP (granulated TSP) is obtained in this way, with very good storage and handling properties.

Economical and with high nutrient content, ammoniated phosphates such as mono- and diammonium phosphate (MAP, DAP) are another popular choice of fertilizers. They are obtained when ammonia (liquid or gaseous) is added to the weak phosphoric acid. Phosphate fertilizers production flow-cart can be illustrated in the following figure :

Corrosive conditions caused by acids such as phosphoric and sulfuric acid impose an extra care when choosing the suitable materials for the equipment. Depending on the rock impurity content, fluoride and chloride influence can also be considered. see the page, valves for fertilizers.